Mud plasters and renders

Practical Action

shrinkage of more than a quarter of an inch (0.64cm) over the 2-foot (0.6m) length of the

box in the shrink box test indicates a soil liable to significant cracking.

• stabilising the plaster by adding cement, lime, bitumen, or some other binder in small

quantities. Possible limitations include the cost of the stabiliser and lack of skill in its

proper use.

Bitumen cutback plaster is prepared by mixing hot bitumen with kerosene in a 5:1 ratio, and

then combining one part of that mixture with 20 parts of previously fermented soil and wheat

straw. Water is added and the whole mixed together thoroughly. This type of plaster is applied

in two layers, and the second is applied only after the first has dried.

Lime-soil plaster can be made with one

part hydrated lime mixed with two parts

of clayey soil and 3 to 6 parts sand, the

optimum amount of sand depending on

the clay content of the soil. The quality

of the plaster depends a lot on the

quality of the lime available and the

type of soil.

Another proprietary plaster is ‘dagga-

cement’, a mix of two parts sand to one

part clayey soil to 0.2 parts cement by

volume. This produces a good weather-

resistant plastering mix.To plaster the

surfaces of stabilised soil blocks, and

for these surfaces only, a coating of a

stabilised mud slurry may be painted

on. This slurry is prepared by mixing

one volume of cement with two of mud.

The final mix should have the

consistency of paint, allowing it to be

applied in a very thin coat. For

decorative appearance, the colour of the

clay stands out better if white cement is

used rather than Ordinary Portland

Cement. Red cement has sometimes

also been used for this reason.

In all cases it is preferable to

experiment with different mixes to find

which one gives the best results with a

given soil, rather than accept a general

plastering recipe.

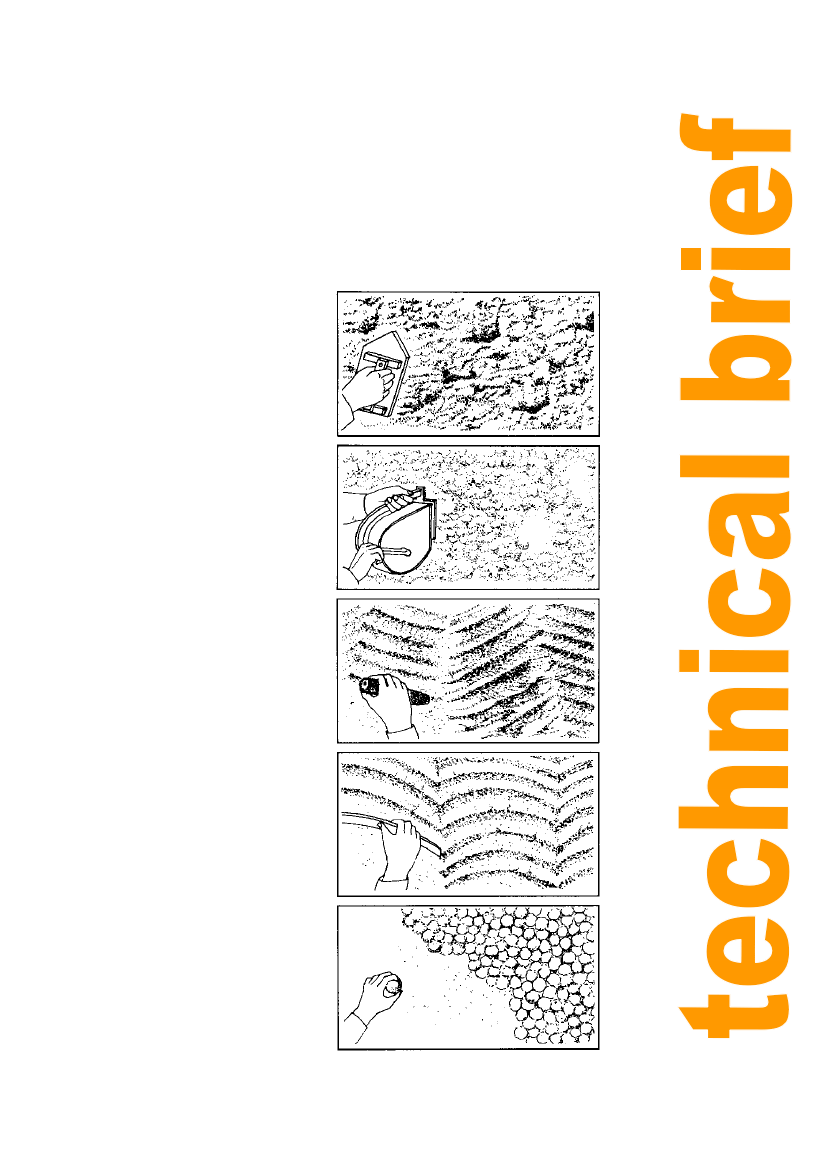

Application: Good practice

There are general rules to follow when

applying all plasters. Firstly, the wall

surface has to be prepared well. This

can be done by scrubbing off all the

surface dust and loose material with a

metallic brush. Then the wall surface

must be moistened to stop water being

drawn out of the plaster layer into the

wall. If the plaster is applied in two

coats, the first layer must be applied

with force and be no more than 20mm

thick. Before hardening of the first

layer is complete, its surface must be

4

Figure 4: The final coat of render or plaster

can be applied to produce a decorative finish.